Tools

Longer life and quality

The development of vacuum coating technologies has led to PVD becoming an irreplaceable final step in tool manufacturing. Extremely high hardness values and an extremely low coefficient of friction are an ideal solution for a wide range of tool applications, and these two factors ensure a significant extension of tool life. This improvement is characterized by the reduction of heat generated during cutting, but also by the high temperature stability of special coating solutions that ensure that no adhesive wear occurs.

The unique properties of tool materials such as high-speed steels or carbides (i.e., their microstructural state and heat treatment history) make them highly applicable to PVD technology. These materials can be exposed to higher process temperatures, resulting in even better coating quality.

Coating process for tools

PVD coating

TECHNO-COAT offers several coating solutions for tooling applications. In general, all solutions lead to the improvement of the crucial properties, but it is very often necessary to define which property takes precedence (hardness, coefficient of friction, temperature stability or others).

Use cases

- Shank tools

- Knife

- Rollers

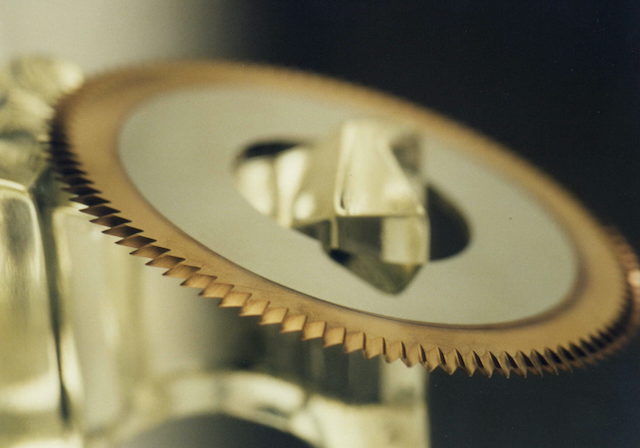

- Gearbox

- Saw blades

Why tool coatings from TECHNO-COAT?

- Extremely long shelf life

- Excellent hardness

- High temperature stability

- Low coefficient of friction